The injection vulcanization process of cushion belt mold is a new processing technology in the production of rubber products.

Its characteristics are: shorten curing time, reduce preparation process in production, reduce labor intensity and improve production efficiency.

The principle of rubber injection vulcanization is that the linear macromolecules of rubber cross-linked into a network or body structure under the action of vulcanizing cross-linking agent. The process is a chemical reaction. The completion time of chemical reaction decreases with the increase of reaction temperature. The time needed for rubber vulcanization to reach the same degree of vulcanization is shortened by about half every time the temperature is increased by 10 °. Of course, the change of chemical and physical properties of rubber during vulcanization is related to temperature and time. The key to ensure the properties of injection vulcanized products is to choose a reasonable vulcanization time and temperature.

The mold structure and forming principle of products formed by different forming methods are different.

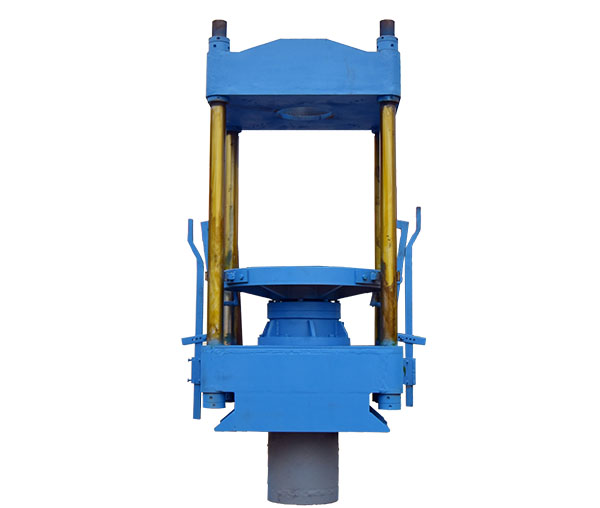

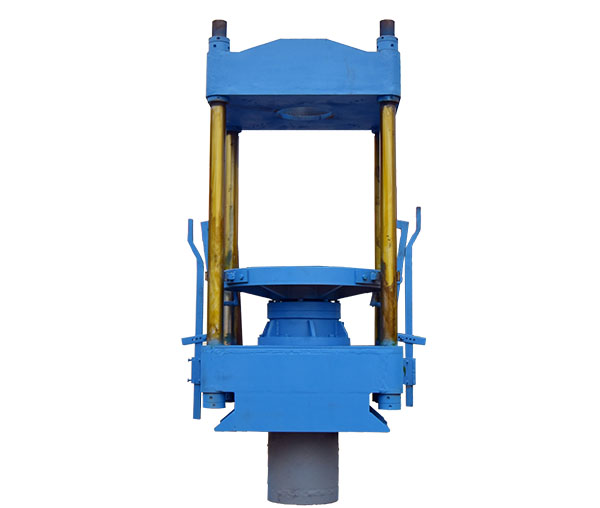

Injection mold:

The material is added into the barrel of the injection machine. Under the action of the screw or plunger of the injection machine, the material is transported forward. Under the action of the screw and the external heating device, the material changes from solid state to molten state, and then the function of the screw or plunger of the injection machine is injected into the cavity of the mold through the pouring system of the mold. Thermoplastics in plastics are produced by multi-purpose injection mold, and rubber products are produced by injection mold more and more.

Features: complex die structure, suitable for the production of large, thick wall, thin wall, complex shape, high dimensional accuracy of products; high production efficiency, stable quality, can achieve automatic production.